BK Aerospace has the complete modern manufacturing facility and equipment needed to meet our customers’ strict product requirements. These often include items of various sizes, shapes and complexities. Below is an overview of our manufacturing equipment and capabilities. For a complete description of our major shop and specialty equipment that BK currently has available, click on the Equipment link.

Shop equipment:

- 3,4, and 5 axis CNC Milling machines

- 3, 4, and 5 axis CNC Lathes, and Multitasking machines

- Manual mills and lathes

- Automatic feed Saws

- Wire EDMs

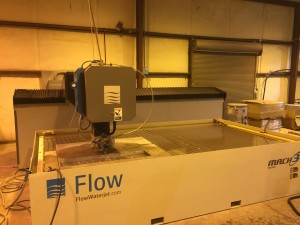

- Water jet machine

- Welding machines

- Hones, presses, and grinders

Large Scale 5-Axis Machining and Integration

One of BK’s key differentiators in the machining business is its capability to machine, integrate, and handle large scale hardware items and assemblies. This is an area that we feel truly sets us apart from our competitors.

Paint, Assembly, and Special Processes

- Mig and Tig welding

- Electron Beam welding

- Prime and Paint

- Ceramic Metallic coating

- Chemical Agent Resistant Coating (CARC)

- Shot peen

- Grit blast

- Stencil

- Silk screen

- Assembly